Technology is Transforming the Heavy Construction Industry

- 03 February 2023

Technology is revolutionizing the heavy construction industry. In recent years, the construction industry has undergone a major transformation, largely due to the development of new technologies. With the help of technology, heavy construction projects can be completed faster, more efficiently, and more safely. Advanced technology is also allowing for the use of more sophisticated materials and designs, resulting in better-built structures. Additionally, technology is making it easier for heavy construction companies to keep track of their projects, as well as the safety and health of their workers.

Benefits of Technology in the Heavy Construction Industry

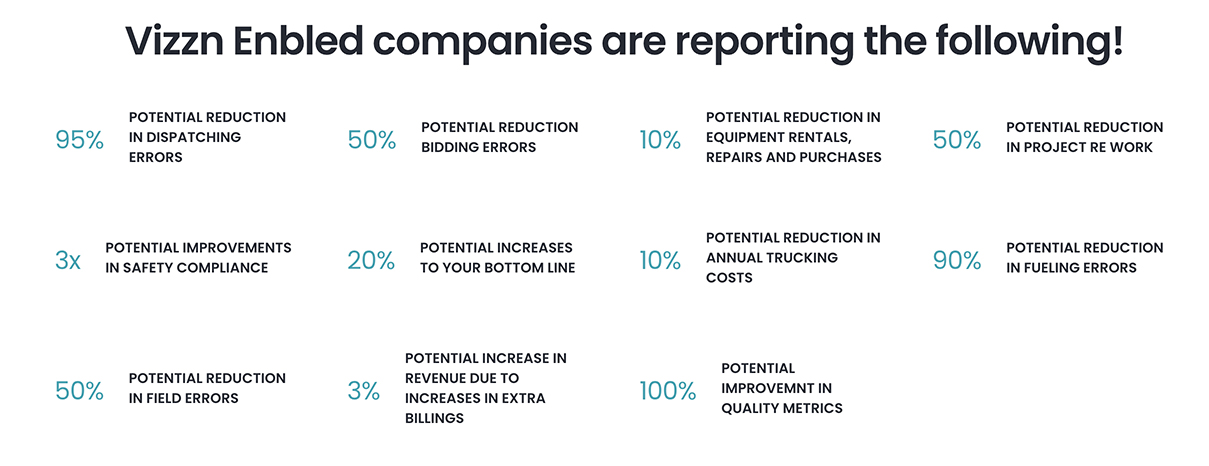

Automation - One of the major trends in the heavy construction industry is automation. As technology improves, more and more construction projects are using automation to help decrease the number of workers required. This has led to a decrease in the number of injuries and illnesses on construction sites and has also resulted in an increase in productivity. According to the National Center for Biotechnology Information, construction site automation has been shown to increase productivity by up to 35% and reduce the number of hours required to complete a project by up to 50%. You might have seen this set of statistics on our home page:

As leaders in construction safety software, dispatching and scheduling, to name just a few, Vizzn’s own statistics are inline with national construction efficiency studies.

These preliminary statistics (over the past couple years) have had a major impact on the heavy construction industry, as it has led to a decrease in heavy construction costs and an increase in companies that specialize in automation. Before entering the construction industry, automation had proven to be highly successful in the oil and gas, mining, and manufacturing industries. Its benefits include increased productivity, fewer injuries, and lower costs. In the last few years, these automation trends have moved into construction.

Challenge of Technology in the Heavy Construction Industry

High Costs - For modern technology to be successful in the heavy construction industry, it must have high availability, high capacity, and high reliability. To reach these high standards, the equipment and devices used in a large construction project need to be incredibly reliable and durable. This is simply not possible for all types of technology, as not all equipment is built to withstand the rigors of the heavy construction industry. This can result in high costs if unnecessary components are used. In addition, some types of equipment are simply too expensive to be used in commercial construction. As the cost of parts increase, so does the cost of the final product. This can result in high-end projects being out of reach for smaller construction companies. As a software solution, Vizzn has a much lower entry point. Imagine for example, you had three automation solutions to consider:

Case 1: A leading construction automation software provider who charges separately for its 8 modules plus charges for each individual user of the software. The annual cost would be somewhere between $50k and $150k a year. For a company with revenues under $10,000,000 (gross revenues, not net profit) - expensive software that isn’t fully utilized is not going to help you gain a productivity advantage.

Case 2: For heavy construction companies looking for solutions on:

- Dispatch and Scheduling

- Estimating

- Construction Management

- Project Scheduling

- Extra Billings

- Quality Control

- Job Site Layout

- GPS (without the actual equipment costs)

- Construction Site Safety

Vizzn may be exactly what you are looking for. How much does Vizzn cost? Entry into construction automation software designed by actual construction people starts at about $500/month. Considering the low cost, even combining heavy construction equipment hardware automation with the Vizzn solution quickly becomes feasible.

Other Examples of Advanced Technology Used in Heavy Construction

- Computer-aided Design/Modeling - A design program scans and photographs a project, and then creates a digital model based on that data. In this way, a construction project’s design is finalized and verified, as well as planned for future changes. This can be done in advance, allowing for more time to be spent on design and less time on construction. The design program can also be used to determine whether building permits are required for a project.

- Remote-controlled heavy construction equipment - Using a remote-controlled system, a construction worker or team can operate heavy construction equipment from anywhere in the world. This can reduce the number of injuries and illnesses that occur as a result of working with heavy construction equipment, allowing for a safer work environment.

Robots in Construction - Robots are proving to be a great addition to the construction workforce. They can help construction workers complete the same tasks that they previously performed manually, with the added benefit of increased safety.

- Robotic Construction Equipment - Another type of robot found in construction is a robot capable of building a structure by drilling and placing rebar.

- Hybrid Vehicles - Hybrid vehicles use an electric motor to power the vehicle, with a gas engine as a backup. As the technology sector continues to advance, hybrid construction vehicles are becoming more common.

Automation in Heavy Construction

Real-time communication and monitoring technology - Real-time communication and monitoring technology is used by heavy construction companies to keep track of workers’ safety and productivity. For example, a construction worker’s work schedule can be monitored, and if they are not completing their shift, they can be notified immediately. This may result in an employee being reassigned to another shift, or possibly being fired.

Virtual Reality in Heavy Construction

Virtual reality is quickly becoming a staple in the heavy construction industry. This is largely due to the fact that virtual reality can be used in special construction projects, such as underwater construction. Construction projects involving underwater technology, such as bridges and tunnels, can benefit greatly from virtual reality. This technology can allow for better visualization of a construction project, as well as make it easier to inspect.

Artificial Intelligence in Heavy Construction

Artificial intelligence (AI) is quickly becoming a staple in the heavy construction industry. This is largely due to the fact that AI can be used in special construction projects. For example, AI can be used to help a construction manager manage the many tasks required to run a construction project. If a manager has the data from past projects to help them predict how long certain tasks will take, they can assign workers to those tasks accordingly.

Robotic Construction Equipment

Robotic construction equipment is quickly becoming a staple in the heavy construction industry. This is largely due to the fact that robotic equipment can be used in special construction projects, such as underwater construction. Construction projects involving underwater technology, such as bridges and tunnels, can benefit greatly from robotic construction equipment. This equipment can make it easier to visualize and inspect the work being done.

Wearable Technology in Heavy Construction

Wearable technology is quickly becoming a staple in the heavy construction industry. This is largely due to the fact that construction workers are often exposed to harsh elements, such as high temperatures and loud noises. Wearable technology can help protect workers from these harmful elements. In fact, wearable technology can be used in any industry that a person may be exposed to harmful elements, such as construction workers.

Conclusion

Technology is revolutionizing the heavy construction industry. With the help of technology, large-scale projects can be completed faster, more efficiently, and more safely. Advanced technology has also led to a decrease in the number of heavy construction jobs, as well as an increase in companies that specialize in automation. With these trends in mind, it’s easy to see why technology is so important to the heavy construction industry. The best way to reap the benefits of technology in the heavy construction industry is to get educated on the new technologies and innovative ways they can be used.